Precision Measurement Services – Roundness

Precision Measurement Services – Roundness

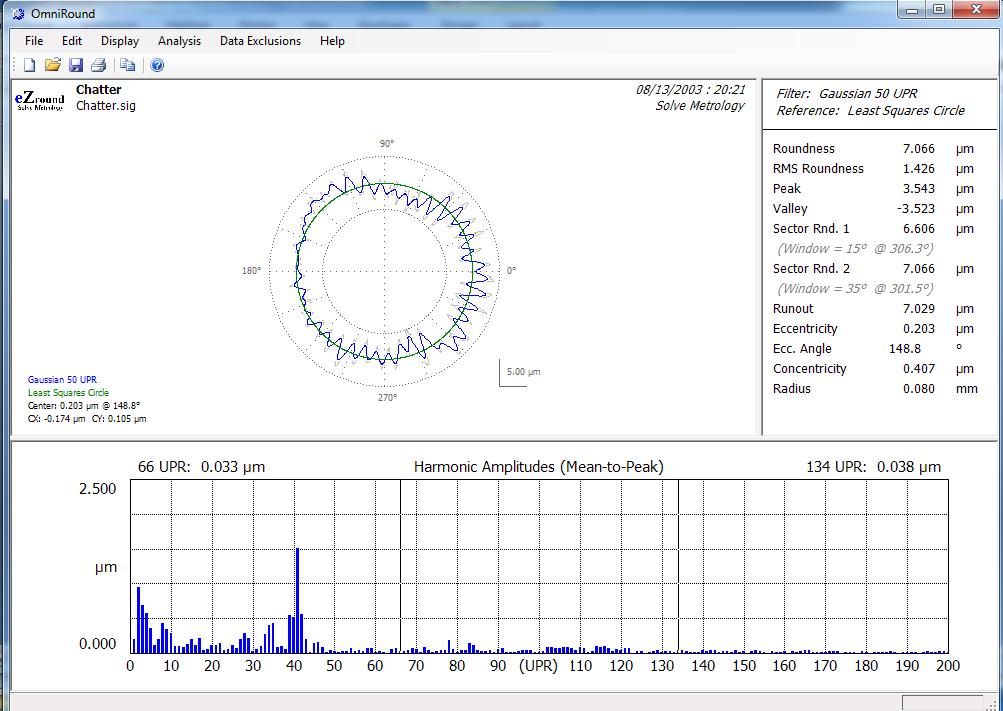

Numerical Engineering provides form and geometry measurement services using some of the most advanced measurement and analysis tools available. Roundness measurement analysis is performed with our eZround system featuring the advanced analysis capabilities of OmniRound software. We can identify many manufacturing problems using a wide range of filtering and analysis tools. Shaft sealing issues, bearing noise, vibration, piston scuffing, uneven wear are just some of the problems that can be solved by correcting roundness errors.

Contact us about solving your most difficult product and manufacturing challenges. We can provide a metrology solution to help you overcome these barriers.

Some examples of parts that benefit from advanced form analysis are:

| Shafts | Valve Bodies |

| Cam shafts and Bores | Pumps |

| Crank Shafts and Bores | Injectors |

| Connecting Rods | Bearings |

| Cylinder Bores | Pistons |

2D Analysis

Detailed two dimensional roundness measurements reveal roundness, ovality, chatter, and lobbing conditions. Harmonic analysis identifies specific lobbing frequencies which can cause noise and vibration.

More comprehensive evaluations can be performed using 3D methods. Cylindricity measurements encompass roundness, straightness, taper, concentricity, coaxiality. But most importantly, it provides the user with a picture of what is going on with the part.

Linear Measurement

Linear straightness measurement capability adds additional detail to the picture.

Effects of Head Bold Up Torque on Cylinder Bore

An excellent example of the value of advanced cylindricity analysis capability is a study of effects of head bold torque on a cylinder bore of a V8 engine. We measure cylindricity on the selected cylinder bore with the block in the “free state” without the head bolted up.

Head Bolts Loose (free state)

Using special fixturing, we can measure the cylindricity again with the head bolted on the block. In some cases we have measured up to .010” head bolt up distortion on certain blocks. This is why you see most modern engines, particularly aluminum engines use very long head bolts which thread down near the crank shaft bearings rather than up near the top of the cylinder bore.

Head Bolts Tight

Similar studies can be performed to determine the effects of heat on engines or other parts.

A 2D view looking down the bores provides another prospective of the effects of head bold up torque. This type of analysis is indispensible for head gasket design which can drastically reduce the effects of head bold up distortion.